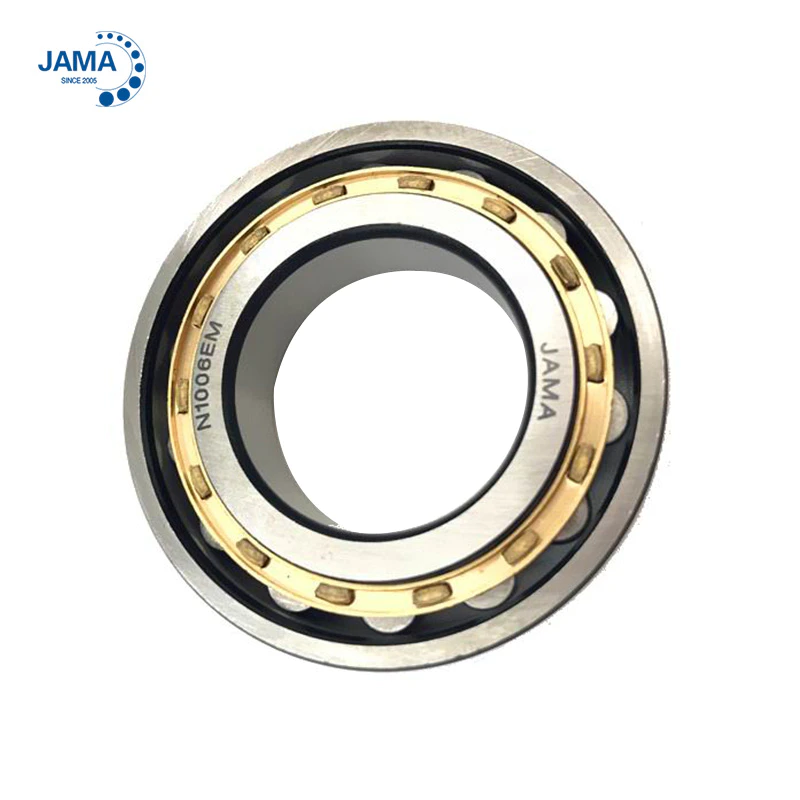

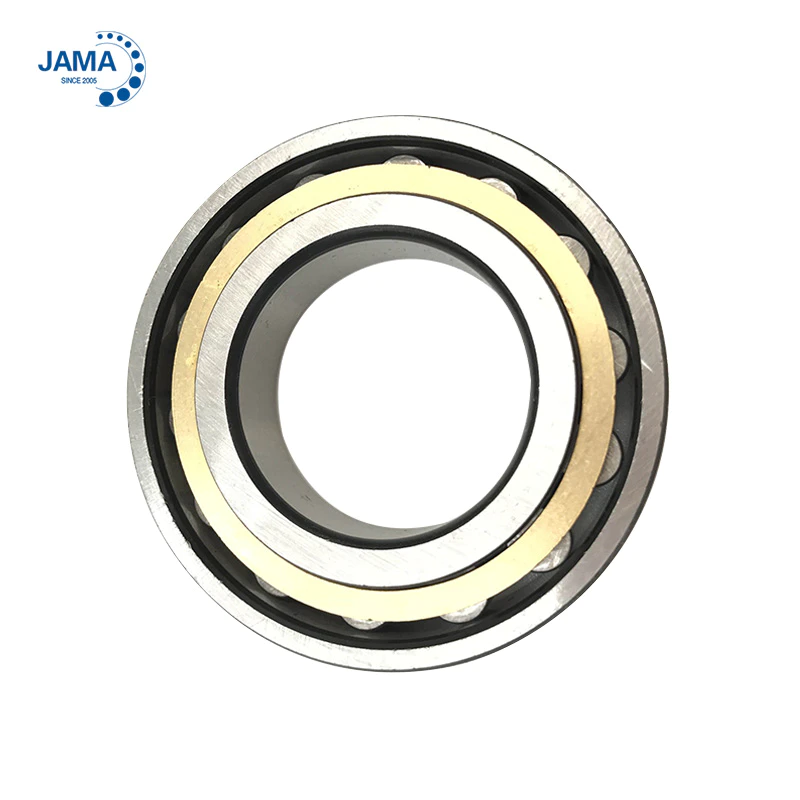

Product: Cylindrical Roller Bearing

Cylindrical Roller Bearing

Type: Single, Double row cylindrical roller bearing

Brand Name: JAMA

Model Number: NU, NJ, NUP, N, NF, NNU NN NH series

Material: Chrome steel, brass/steel/nylon cage

Grade: ABEC-1, ABEC-3, ABEC-5

Clearance: C2, standard (CN) C3, C4 and C5 internal clearance

HOT PRODUCTS

| Bearing type | Single, Double row cylindrical roller bearing. |

| Bearing material | Chrome steel, Gcr15 |

| Precision | P0; P6; |

| Standard size | NU, NJ, NUP, N, NF, NNU NN NH series |

| Packing | JAMA Individual Box |

PRODUCT DESCRIPTION

Cylindrical Roller Bearings are designed to carry heavy radial loads. These bearings are made with a single row, double row sof rolling elements to meet an application’s radial load requirement. Available in many standard series and configurations, they are widely used in multiple industries. The combination of high load capacity, moderate speed rating, and industry interchangeability make it one of the most popular bearing designs.

Cylindrical roller bearings have rollers that provide a modified line contact with the cylindrical inner and outer ring raceways, while the rollers are guided by ground ribs on either the inner or outer ring. The cylindrical shape allows the inner ring to have axial movement relative to the outer ring. This is especially important when accommodating thermal expansion, where both rings must be press-fitted.

Bearing features: High load carrying capacity, High stiffness,Accommodate axial displacement,Low friction,Long service life,Enhanced operational reliability,Separable and interchangeable

Applications: large and medium-sized electric motors, rolling stock, machine tool spindles, internal combustion engines, generators, gas turbines, reduction gearboxes, rolling mills, vibrating screens, and lifting and transportation machinery.

PRODUCT DETAILS

LEAVE A MESSAGE

We warmly welcome both new and existing customers from all the world to contact us for future business relationships and mutual success!